in the electronics, optics, medical and tooling industries.

|

Foam Padding | |

|

SCHRY-WAY

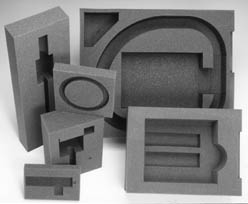

CLOSE-TOLERANCE POLY FOAM INSERTS Our foam shaping department is fully equipped for drilling, slicing, hot-wire milling, band-saw shaping, die cutting and the assembly of close tolerance poly foam inserts. Originally established to provide inserts exclusively for our own line of high-quality hardwood cases, the department has been expanded to process foam on a custom basis for any type of packaging available today. We are essentially short-run specialists but have the capability of handling high-volume runs with efficiency and considerable accuracy. FEATURES

PRICE

LIST |

FOAM IS PERSONALLY GEARED TO YOUR SPECIFIC PIECE(S) OF CARGO. EACH IS DESIGNED TO YOUR SPECS. Our foam shaping department is equipped for drilling - slicing - hot wire - hot wire template cutting - band saw shaping - assembly - etc. There are several variations of foam from which to choose. The most common are polyester and polyethylene: MATERIAL

DESCRIPTION POLYESTER FOAM SOLIDS - STANDARD SIZES Charcoal Gray * 1.8 to 2.0 lbs. Density MIL P 26514 TYPE 1 CLASS 2  POLYETHYLENE

FOAM SOLIDS - POLYETHYLENE

FOAM SOLIDS - STANDARD SIZES Polyethylene plastic foam is a tough, lightweight, flexible but firm foam consisting of millions of closed, air filled cells, that will resist most solvents Available in Black, Blue and Antistatic (Pink) MIL PPC 1752 TYPE 1 CLASS 2 |

(888) 724-7992(toll free)

Home

| AB Series |

MB Series | L1

Series | MD Series

| Foam Padding | Contact

Us